Starting from the motion law of gas-solid two-phase flow, analyzing the dust particles movement and wear mechanism, changing the trajectories of particles from the pneumatic perspective, are a effective measures to improve centrifugal fan wear.

|

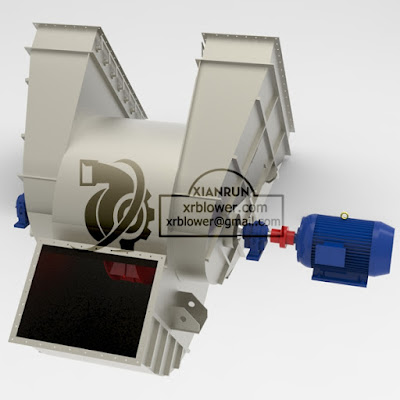

| centrifugal fan air intake by xianrun blower |

Selecting reasonable fan air inlet is to improve the fan inlet condition and dust air flow movement mode, so as to reducing centrifugal wear. Practice has proved that the centrifugal fan will have serious uneven wear when using common cylindrical inlet; when the air inlet is modified to horn type inlet, will improve blade wear.

|

| centrifugal fan air inlet by xianrun blower |